ENGINEERING

Collaborative Design Service

A quality die casting begins far before the die is built. Engineering in the design phase is the most critical element of the project. While in the design phase, we are able to work with your engineering team to assist in the DFM (design for manufacturing) process that meets your requirements and expectations while optimizing manufacturability and then work closely with you throughout every step of the launch process to production. Besides, we will work with downstream process experts such as quality, machining, and finishing for opportunities to keep the overall manufacturing costs to a minimum.

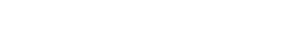

Mold Flow Simulation and CAD Design

Our team will work with your engineering team to evaluate all tooling features and options which in-turn will help improve die life and minimize potential problems during the casting process. There is nothing more important than die cast dies during the die casting process. The well-known knowledge has shown the casting success is highly based upon the quality of the molds. A well-designed mold will last long and run productively. We understand every part design is unique and specific to that die cast tool that will be used to cast the part. In recognition of that fact, HH performs the CAE (computer aid engineering) simulation with the cutting edge modeling (Solidworks ®, AutoCAD ®) and flow simulation (Hitachi ADSTEFAN) software to optimize die design, and prevent casting from potential problems in the early stages of development . Moreover, we have our own die shop to build durable, affordable, and precise mold for your components.

Quoting Checklist

During our initial quoting of a new project, we look for the following design criteria prior to sending a formal quote:

- A dimensioned 2D print and 3D model showing casting/machining tolerance to be manufactured.

- Aluminum casting alloy or required material properties.

- Expected annual volumes.

- Anticipated order schedules/quantity.

- Any critical dimensions or special characteristics related to the casting or machined part.

- Surface finish requirements.

- Allowable draft angles.

The answers to these and many other questions are critical to help develop and optimize casting process and tooling plan. It is our goal to provide our customers with quality castings delivered reliably at the lowest possible cost.